Investment casting for boiler accessories and combustion parts

The commonly casting material for boiler accessories and combustion parts is heat-resistant steel, the widely used is HH, HK, A-27 GR60-30 and CL1/ G17CrMO5-5. The common casting methods are silica sol investment casting and sand casting. For the investment casting , The weight can be casted from 0.01g to 120kg with the tolerance CT5 to CT7 and the surface roughness from Ra 3.2 to 12.5. For the sand casting , The weight can be casted from 5kg to 2500kg with the tolerance CT11 to CT13 and the surface roughness from Ra 25 to 50.

| Technic | Material | Weight | Tolerance | Roughness |

| Silica sol investment casting | HH,HK,A-27 GR60-30, CL1/G17CrMo5-5 | 0.01-120KG | CT5-CT7 | Ra3.2-12.5 |

| Sand casting | HH,HK,A-27 GR60-30, CL1/G17CrMo5-5 | 5-2500KG | CT11-CT13 | Ra25-50 |

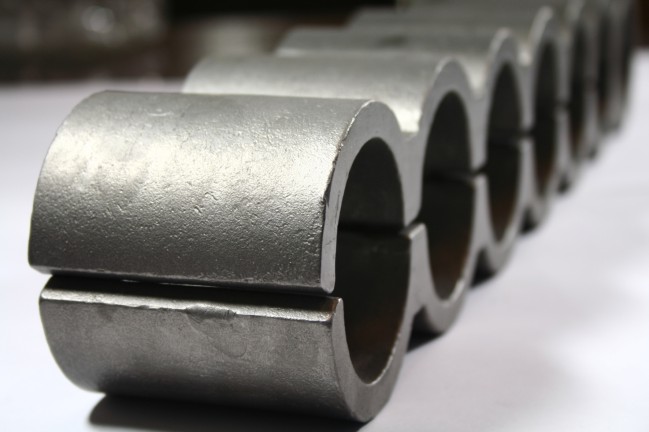

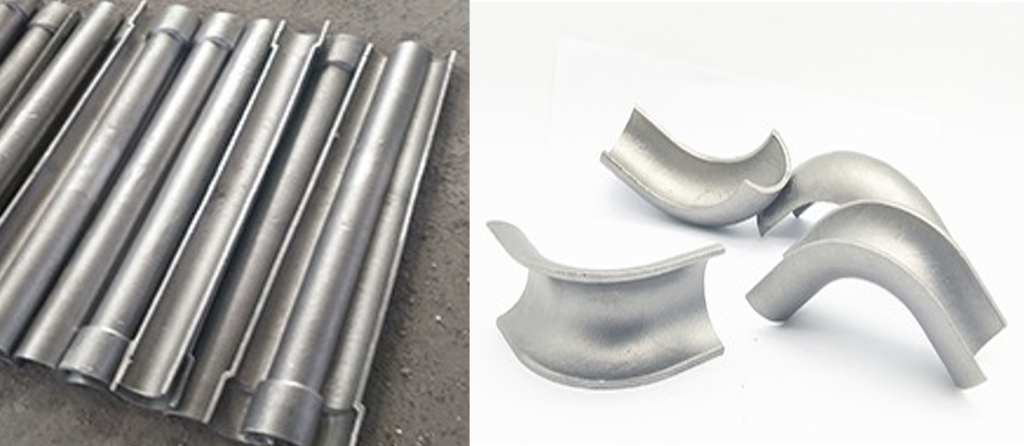

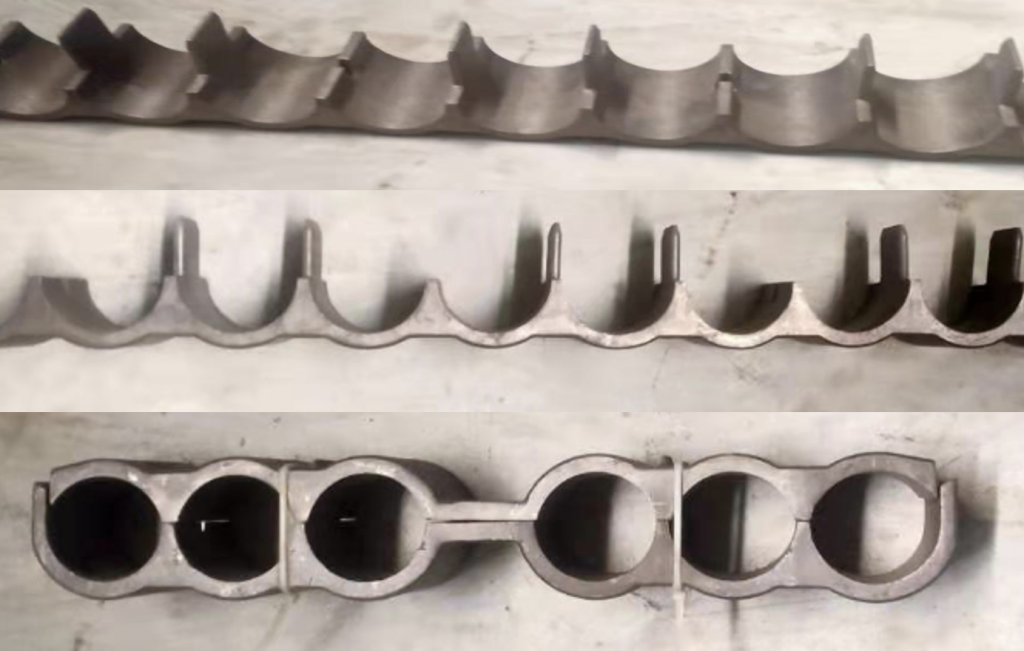

The Common boiler accessories are hood, such as double hole arrow hood, porous cap, grille hood, “7” type hood, and support block, sliding block, male and female buckle, grate hanging plate, pipe clamp, anti-wearing tile and so on

TCC is experienced in manufacturing the boiler accessories and combustion parts .If you have any inquiry , our technician are happy to discuss with you , please feel free to contact email alina@tcc-casting.com