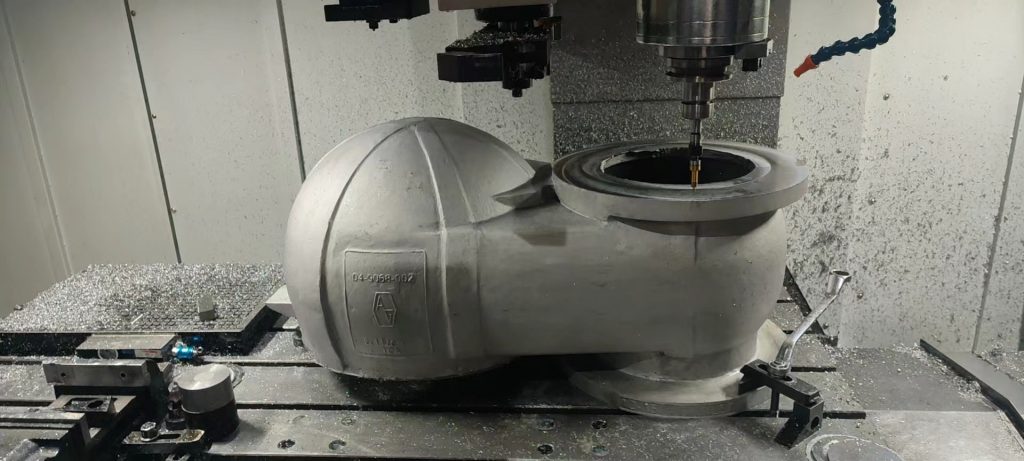

12 inch pressure valve material A356

A356 is widely used to cast components like aircraft parts, pump housings, impellers, high velocity blowers and structural castings .

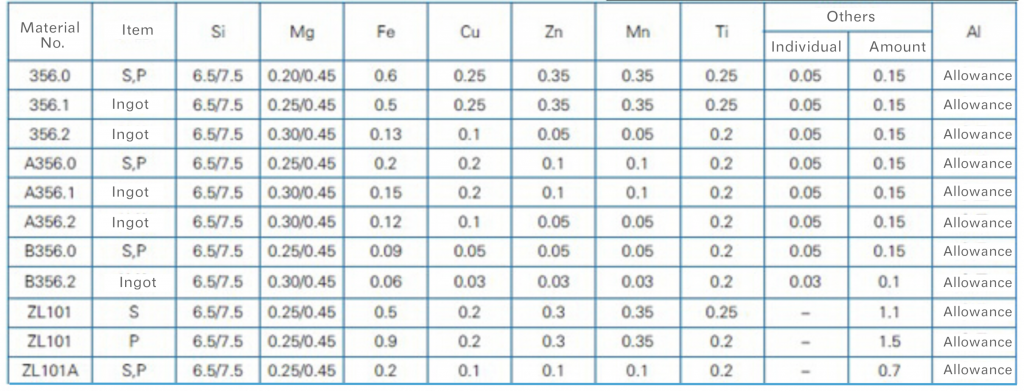

A356 alloy is a class of alloys in the Alcoa Standard series. This series has three alloys: A356.0, A356.1, and A356.2, which are part of the 356 Series. Its composition is shown in Table 1.

Table 1 Comparison of chemical composition between Alcoa 356 series alloy and domestic ZL101 series aluminum alloy Unit: %

-The 356 series is the American standard brand, and the ZL101 series is the Chinese standard brand;

-S-sand casting, P-metal casting;

-The Chinese standard also makes separate provisions on the content of Pb and Sn impurities (the American standard classifies them as other impurities) : Pb<0.05 Sn<0.01(corresponding to ZL101), Pb< 0.03 Sn< 0.01(corresponding to ZL101A);

-356.2 alloy has a maximum Fe content of 0.25%.

It can be seen that the chemical composition design of Al-7Si-Mg series alloys has the following characteristics: no matter the American standard or the Chinese standard, the common feature is the same composition range of Si elements: (SI-6.5/7.5); For magnesium, the Mg required for casting material is 0.25~0.45; In the American standard, the requirement of magnesium element in the ingot is increased by 0.05%, namely 0.30~0.45, mainly considering the burning loss of magnesium element during smelting.

The main difference in the chemical composition of this series lies in the regulation of impurity content. For the American standard, the first letter of the brand indicates its performance grade, so that the user according to different application requirements to determine the brand. The first letter of the letter B is the highest performance, so the requirements for impurities are also the most stringent. Alloys without a first letter have poor performance and are mainly used in common applications. The A356 series is an in-between material. The number at the end of the brand (0,1,2) is the limit of various impurities according to different occasions. A356.0 is the material composition specified for the material of the castings produced; A356.1 and A356.2 are two kinds of components formulated for the production of raw materials for castings, namely ingot, according to different requirements of use.

ZL101 series mainly defines the material of castings, with high requirements for ZL101A; ZL101 is generally required. The Chinese standard does not specify the composition of the raw material used for casting, namely the ingot.

TCC has rich experience in producing cast aluminum to meet your design. If you have any inquiry on custom parts, Please feel free to send us the CAD drawing and let’s discuss!