Aluminum alloys have the advantages of good plasticity, corrosion resistance and lightweight, making them ideal for automotive manufacturing, aerospace, shipbuilding and other fields. Due to the increasing demands of aluminum castings, the aluminum casting industry is rapidly growing in China. At present, the main aluminum casting methods are: pressure die casting and gravity die casting. As the professional aluminum casting company in China, let’s talk about the main differences between pressure die casting and gravity die casting.

Gravity Die Casting

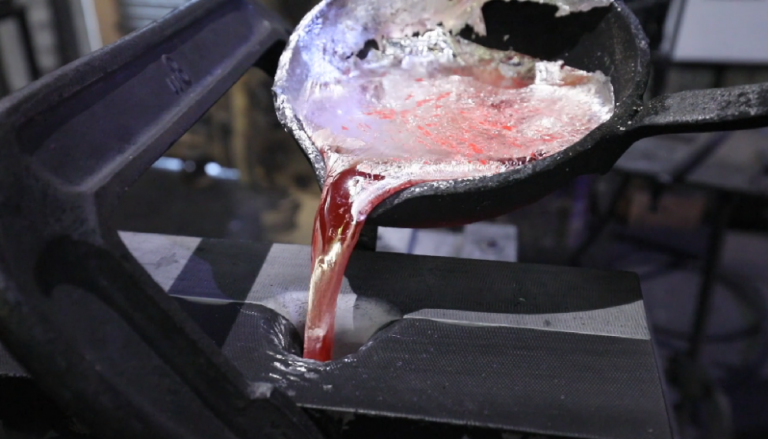

Gravity die casting is a form of die casting that is prefect to creat repeatable high quality components in a range of low temperature metals. It involves a simple pouring of the molten metal into the mould under the force of gravity only and without any additional force applied.

Gravity die casting process can make parts that are net-shaped have tight tolerances. Sometimes, it is also called as permanent mold casting. Different from pressure die casting, pressure die casting is used for parts that are slightly heavier, larger in size, and have higher structural requirements than pressure die casting. For greater complexity of design, both the sand cores and metals could be used.

A unique feature of the gravity die casting method is that it can handle heat treatment of high strength aluminum alloys that pressure die casting still cannot. Suitable for castings requiring complex intricate coring and small production runs.

Pressure Die Casting

In pressure die casting, molten metal is injected into a steel mould under high pressure and high speed, the cooled for solidification to form a solid metal component. Typically, the process itself only takes a few seconds and is a quick reliable and cost-effective manufacturing process with a high degree of precision and repeatability. Different from gravity die casting, the process is automated and the liquid metal or alloy is injected under high force into a hardened steel tool.

The pressure die casting process has the advantage of excellent process repeatability. Generally, the surface finish of pressure die cast parts is achieved from the surface finish of the tool that produces it.

The unique feature of the gravity die casting method is that it can make parts whatever complex or thin the part is. Also, good strength can be obtained after the workforce of high pressure. The only limitation is that it costs higher mould cost compared to gravity die casting, and is not so cost effective if the volume is small.

Gravity Die Casting or Pressure Die Casting for Your Project?

When deciding a die casting method for your design, it is important to analysis the structure of the part, if the part is ratively thin and the quantity is large, then pressure die casting is preferred. But if the part is ratively thick and the quantity is small, it is ideal to consider gravity die casting process. If you are looking for a quality die casting supplier for your project, pls do not hesistate to contact us!