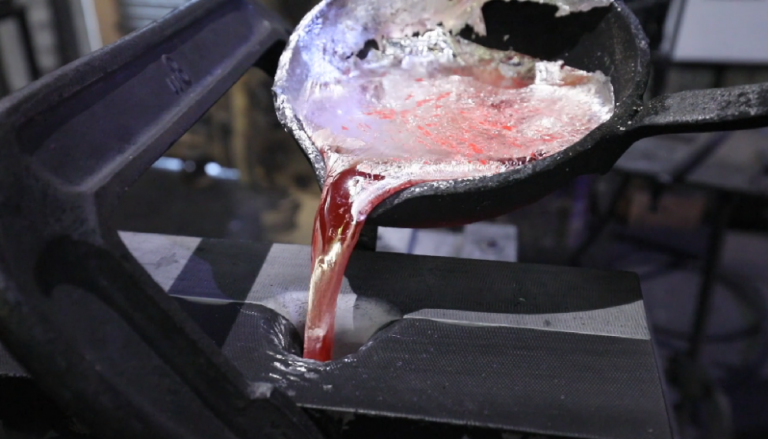

In TCC Casting, our aluminum gravity die casting technique can make quality cast aluminum parts for a range of industries, including Marine, Cars & Trucks, Gas Turbines, Compressors, Pumps, Valves, Medical Equipment, etc. What is Gravity Die Casting? Gravity die casting, may also called as permanent mould casting, is a typical die casting technique to creat high quality metal components which have low melting points, such as aluminum and zinc alloys. In gravity die casting process, the molten metal is poured from a ladle…