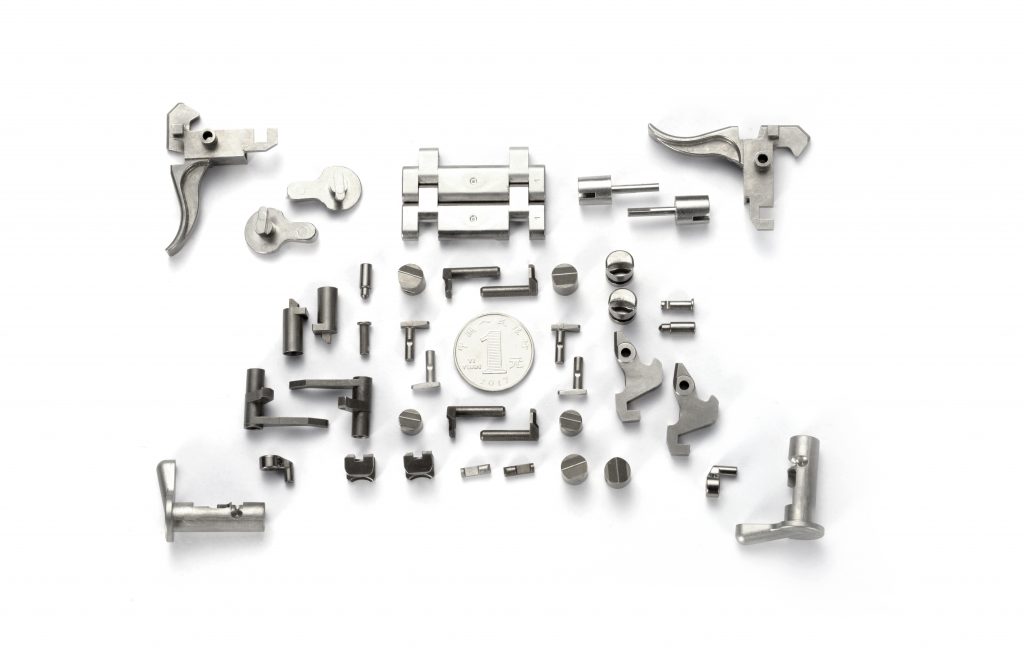

Screw /Pin of hardware applied inn Kitchen or bathroom For these kind of small stainless steel parts made of 304 with mirror effect of surface which is high end of hardware for kitchen and bathroom .Most of these kind of parts are plastic with zinc plating .The key process for this part is mirror polishing which makes the part looks more nicer surface and valuable. How’s the price for this part? Depends on different quantities , it has different process…