Considering the mechanical performance , C45 is better option for rocker arm than the aluminum alloy , however, C45 is easy to be rusty while aluminum alloy is light with good appearance .but what aluminum alloy is suitable, AlSi7Mg or AlMg10?

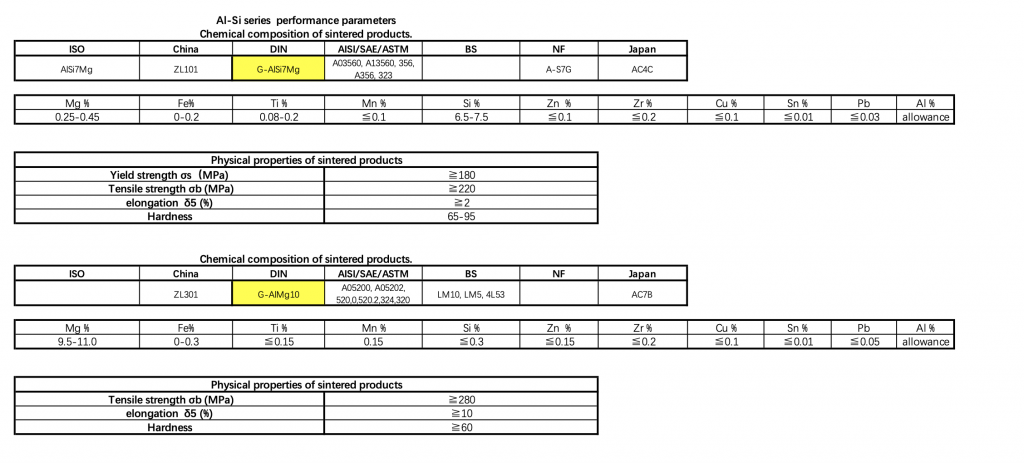

According to customer’s requirement and the materials parameters, TCC found the close material is AlSi7Mg or AlMg10 for gravity casting.

For AlSi7Mg, It is composed of simple composition, easy melting and casting with good casting performance, good air tightness, the welding and cutting performance is also fine, but the mechanical properties are so so . It is Suitable for casting parts with thin-walled, large area and complex shape , or not high requirement for strength, such as pump shell, gear box, instrument shell, and parts of home appliance parts . It mainly used for sand casting and gravity diecasting.

For AlMg10, it has the strongest corrosion resistance performance in existing aluminum alloys .The cutting performance is very good, welding performance is relatively good, the good strength and anodic oxidation performance , but the casting process and the operation is also complicated, furthermore , it is easy has loose, hot crack and other defects. It is suitable the parts with large load in corrosive medium such as working temperature of under 150 degrees in ocean, eg. The components in Marine or ship, pump shell, impeller, frame and other parts in the petroleum industry . The technic is mostly sand casting .

TCC’s technician can draw the 3D drawing and propose the material for customer ‘s decision. If you have any inquiry , please feel free to contact TCC Casting.