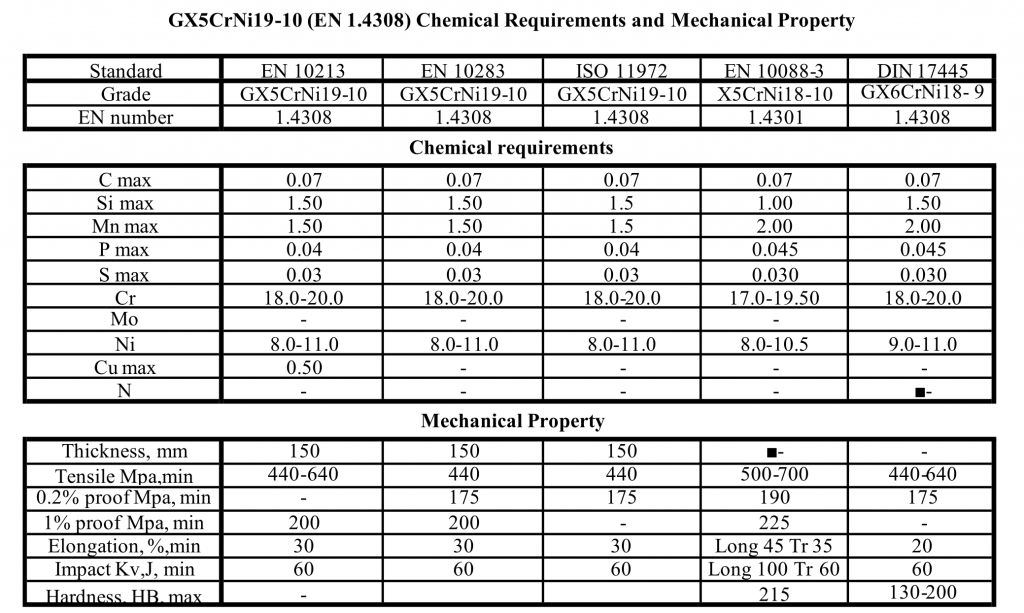

GX5CrNi19-10 (EN 1.4308) is same stainless steel material as SS304, EN 10213: 2007 Steel castings for pressure purposes EN 10283: 2010 Corrosion resistant steel castings ISO 11972:2015 specifies cast steels for general corrosion-resistant applications.X5CrNi18-10 (EN 1.4301) is the similar grade in standard of in EN 10088-3

GX5CrNi19-10 (EN 1.4308) similar grade:

American: ASTM A351 CF8 (J92600)

American: ASTM A743 CF8 (J92600)

American: ASTM A744 CF8 (J92600)

American: ASTM A297 CF8 (J92600)

Japanese: JIS 5151 SCS13

Chinese: GB/T 12230 ZG0Cr18Ni9

France: AFNOR Z6CN18.10M; Z6CN19.9M

UK: BS3100-4 304C15

Korea: KS D4103 SCS13

Germany: DIN 17445 GX6CrNi18-9

Heat treatment process: Solution annealing + water quenching (+AT)

Heat to 1050-1150°C for sufficient time to heat casting uniformly to temperature and water quench

GX5CrNi19-10 (EN 1.4308) BENEFITS

Corrosion and pitting resistance Better for abrasive applications

Higher strength than standard stainless steel Improved ductility and weldability

Better resistance to embrittlement

GX5CrNi19-10 (EN 1.4308)APPLICATION

it’s the most popular stainless steel used in such Pump industry, Machinery spare part ,Automobile industry , Food industry…

If you have some parts which could be machining directly or cast , let’s discuss what kind of technic is most fit for you . TCC’s technician could design the drawing for you according to your idea , or propose the most suitable technic for you . Contact TCC casting .