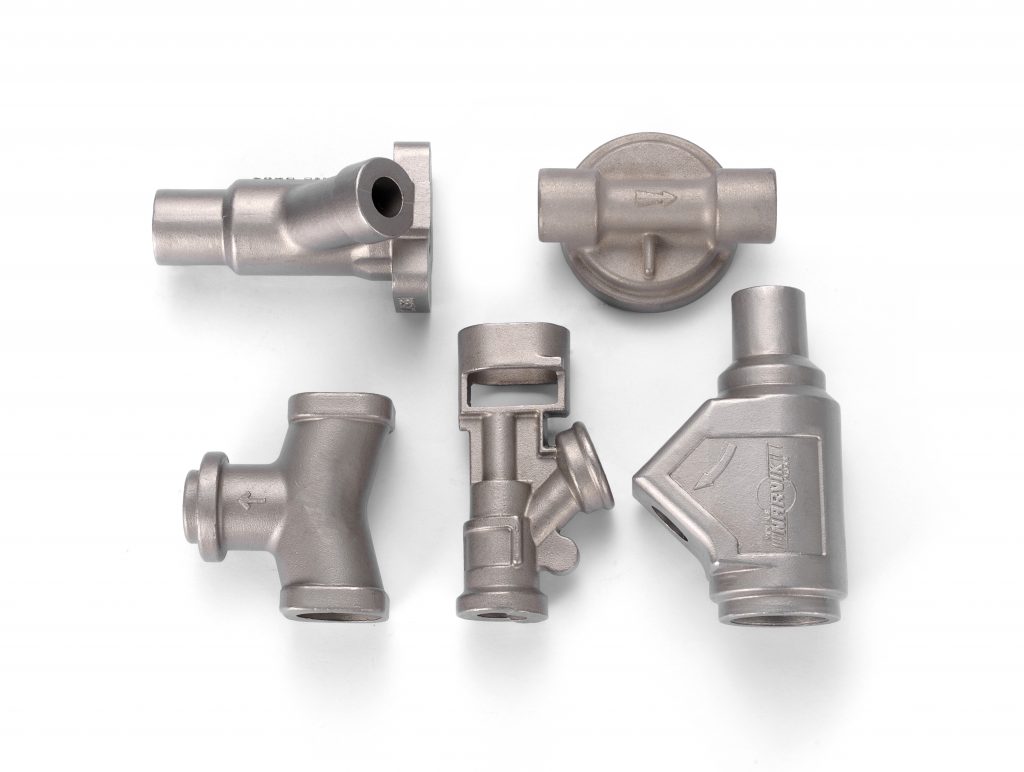

For the wide application of valves for pipelines, transportation and industrial production all need valves for controlling, TCC Casting is the reliable manufacturer and supplier for valve manufacturers . We can make all kinds of cast valve components for check valve, butterfly valve, ball valve, gate valve, control valve, globe valve, plug valve, ect.

Lost Wax Casting: Is able to make cast steel valve components, like carbon steel, stainless steel, and other cast steel alloys. Lost wax casting is a precision casting method for valve components, so we can achieve good dimensions and tolerances, smoother surface. Stainless steel valve casting parts are widely used in silical sol casting process, which is another lost wax method. We can use this casting process for butterfly valves, ball valves, ect.

Lost Foam Casting: This casting method is more suitable for making precison cast iron valve parts, which can also get good surface finish and sizes, such net shape or near net shape valve castings will need no machining or just little machining allowance.

Sand Casting: Also a casting process for valve casting parts. Sand casting is suitable for both steel and iron valve castings. Compare with lost foam and lost wax castings, it is more suitable to make larger valve components, so normally, we will need to leave more machining allowance for further machining operation. The max weight we can cast is around 2 tons per piece.

Materials of Valve Casting Parts are as following:

Carbon Steel (mainy for high pressure valve castings): WCA, WCB, ZG25, ZG200-350, ASTM A216 WCA/WCB/WCC..

Stainless Steel: SS304, SS316, PH17-4, ASTM A351 CF8/CF8M/CF3/CF3M, ZG0Cr18Ni9, zg0Cr18Ni12Mo2, ZG00Cr18Ni10.

Gray Iron: HT200, HT250, HT300, HT350,GG15, GG20, GG30, FC200, FC250, FC300, ASTM A48 CLASS NO.20,NO.25,NO.30, NO.35.

Ductile Iron: QT400-18, QT500-7, QT600-3,GGG40, GGG50,GGG60, FCD450-70, FCD400-15, FCD500-7, FCD600-3, ASTM A536 ( 60-40-18,65-45-12, 80-55-06).

Other capabilities to supply valve castings

To supply finished valve casting parts, we have machining equipments as well (NC lathe, CNC, boring machine, drilling machine, ect) for different machining requirements. Besides, we also have hydraulic testing capability to ensure workable valve castings.

For large dimensions valve casting parts, to avoid casting defects, it is necessary to do magnetic particle testing and ultrasonic testing after casting.

From the material selection, multiple casting options, machining serves, you can have proposal from TCC , Please contact us once you have demands of valve components.