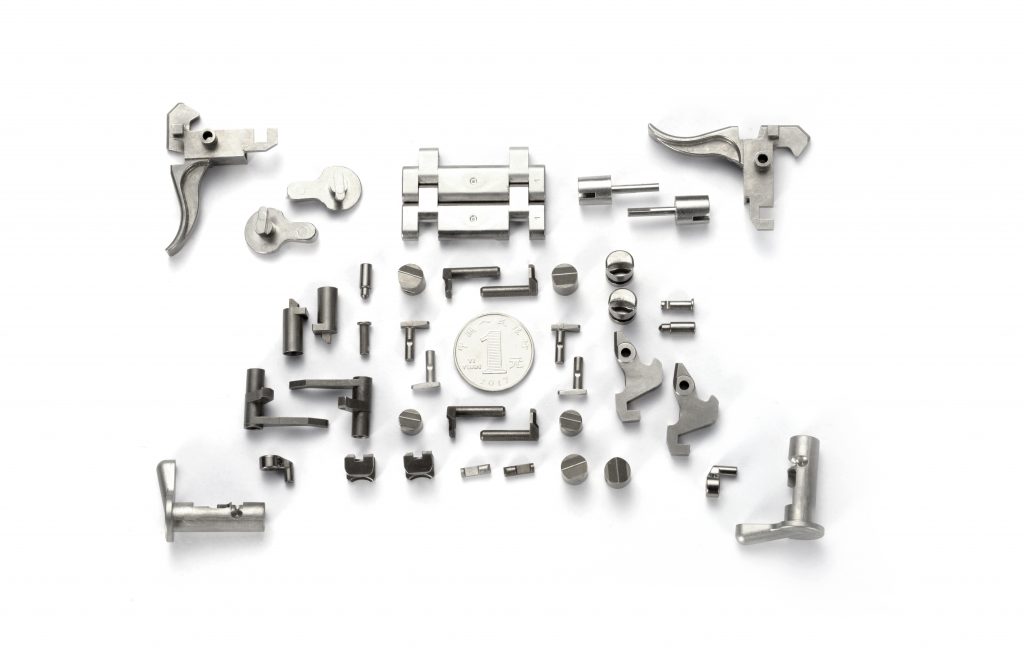

Metal injection molding for small connector Metal injection molding is a metalworking process in which finely-powdered metal is mixed with binder material to produce a “feedstock” which is then shaped by injection molding. The complex parts just need to be shaped in one step during the whole process. After molding, the part undergoes conditioning operations to remove the binder and densify the powder. As the good performance on roughness , tolerance ,high efficiency than other technic .The metal injection molding…