To improve our services of investment castings and deliver finished products to our customers, apart from producing casting blanks, we can also supply value-added services in below:

Engineering Service

With many years of investment casting experience, our engineers knows what works best in the investment casting process. Sometimes, just a few small changes to a part design can add up to big savings in both production time and cost. What’s more, such changes will greatly improve the working performance of your products. Therefore, we offer engineering and design assistance to make your investment cast parts easier and less expensive to produce.

Our team will work closely with your product engineers to optimize part designs for more efficient production and cost saving. Maybe we don’t know the entire process involved in the application of your product, we can make the casting process easier by identifying and eliminating potential problem areas in your designs. Optimized designs can reduce or eliminate the need for machining or other secondary operations, and can significantly reduce material waste, thus to save the whole production cost of products.

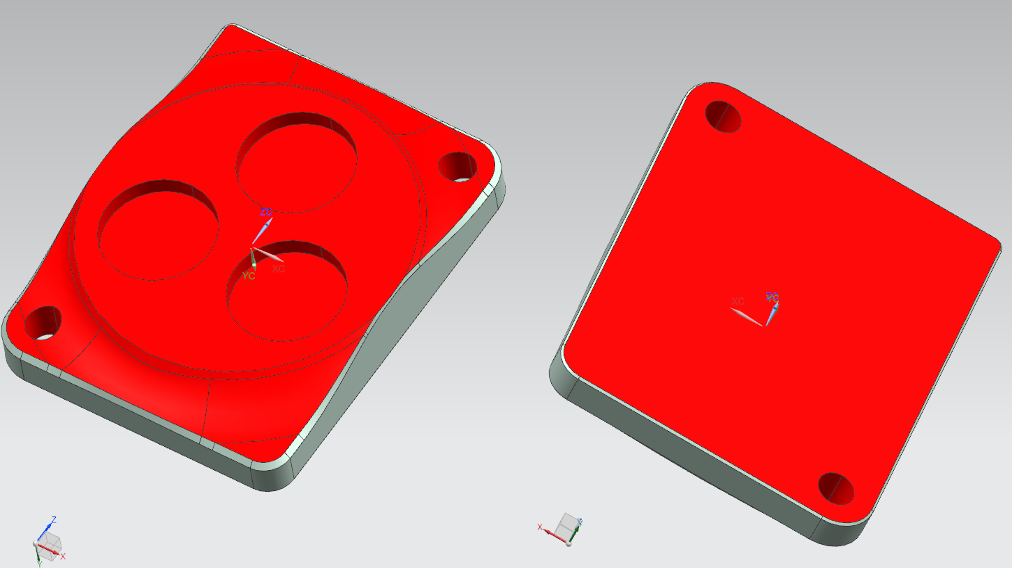

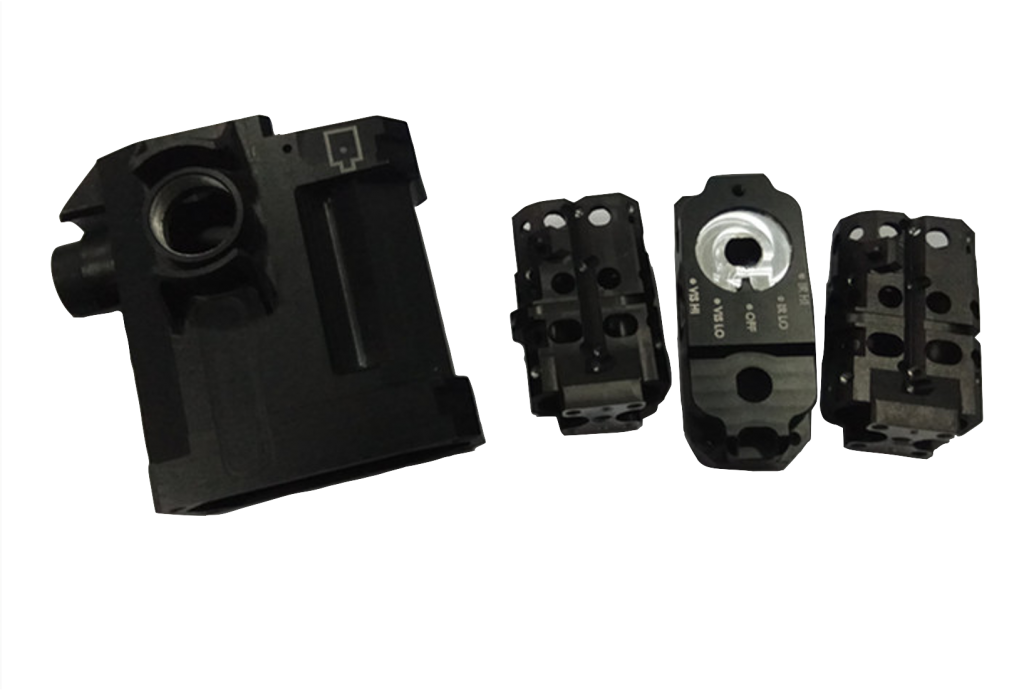

Machining Service

Although the high quality investment castings made by our foundry are unbeatable, for some special products with tight tolerances, we will still need to carry out machining operations in steps like boring, drilling, facing, ect. The machining operations can be divided into rough machining and precision machining. Rough machining is operated by general machining equipments, such as boring machine, drilling machine, NC lathe, and so on. However, precision machining is needed when there is a tighter tolerance requirement, such precision dimensions and tolerances will be done in CNC, so by comparision, the precision machining cost will be much higher than that of rough machining.

TCC Casting, can supply both rough machining and precision machining services for our customers. Of course, to save machining time and cost, our team will give you a best solution for less machining.

Heat Treatment Service

Heat Treatment is utilized to change the chemical and physical properties for better working performance. Common heat treatment ways after investment castings include: Normalization, Tempering, Quenchining, Case Hardening, Carbirizing, Quenchining and Tempering, ect.

We have the ablility to offer in-house heat treatment service for our customers, and creat harder, tougher, and more durable products. Heat treatment is vital for investment cast components, especially when products work harsh or caustic environments where extreme durability is required. The stronger your products are, the longer their service life will be. We apply our heat treatment process to many of our investment casting components per your particular specifications.

Surface Treatment Service

To protect investment castings from rusting, investment castings are usually dipped into anti-rust water or oil before package. So oil/water anti-rust paintly is the most common way for investment castings. But there are also some other surface treatment methods applied in investment castings, such as color painting, powder coating, galvanization, Electro polishing, ect. Each type of surface treatment has their own fuction or characteristics.

We can provide a range of post treatments which are carried out either on site or via our approved sub contractors. More and more of our customers are benefiting from the extensive range of investment casting finishes that we have.

Custom Package Service

For exported investment castings, as the delivery time is quite long, especially sea shippment, we need to protect the products from any damage. In general, we will pack products with ploybag,and then put into standard wooden cases.

Besides, we can also provide custom package services with logo marked for our customers accordingly. Just pls send us the pack details you need.

Non-Destructive Testing Service

Non-destructive testing (NDT) is a highly valued technique and most reliable way for inspecting investment cast components. These tests are performed in a manner that does not affect the future usefulness of the product. Non-destructive testing allows for simple product evaluation and problem troubleshooting, enabling our investment casting specialists to thoroughly inspect your finished cast components without damaging or altering them.TCC has the Non-destructive testing equipment and also qualified engineers with certificated to conduct this inspection .

Besides RT, MPI (Magnetic Particle Inspection), UT (Ultrasonic Testing) , DPI (Dye Penetrant Inspection) are also can be tested in TCC Casting .