What is carbon steel?

Carbon steel is an iron-carbon alloy with a carbon content of 0.0218%~2.11%. It contains small amounts of silicon, manganese, sulfur, and phosphorus. Generally, the higher of carbon content in carbon steel, the greater of the hardness, the higher of the strength, but the lower of the plasticity.

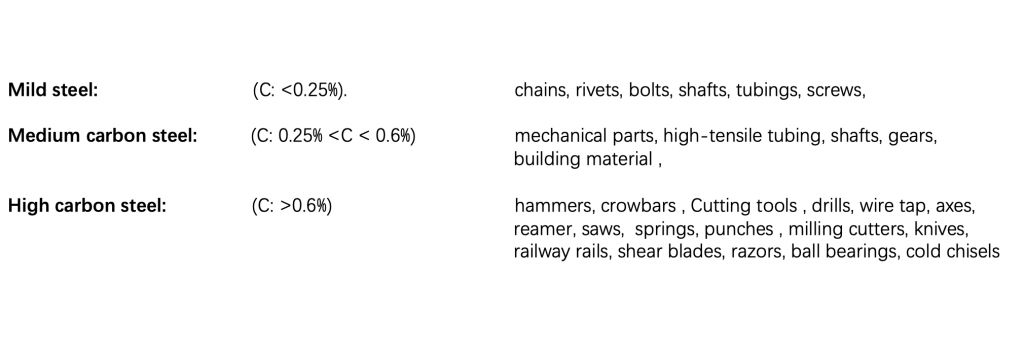

Carbon steel is one of main materials in steel castings. The Classification of carbon steel according to the carbon content.

Low carbon steel (C: <0.25%)

Also known as mild steel, low carbon steel is fit for variety of machining suchas forging, welding and cutting, often be manufactured to chains, rivets, bolts, shafts, etc.

Medium carbon steel (C: 0.25% <C < 0.6%)

Including killed steel, semi-killed steel, rimmed steel. In addition to carbon, it also contains a small amount of manganese (0.70%~ 1.20%). According to product quality, it can be divided into ordinary carbonstructural steel and high quality carbon structural steel. Medium carbon steelhas good performance of hot-working and cutting, but poor weldingperformance. The strength and hardness are higher than that of low carbonsteel while the plasticity and toughness are lower than that of low carbon steel.The hot rolled and cold drawn materials can also be used without heat treatmentor be done after heat treatment. The medium carbon steel after quenching and tempering has good comprehensive mechanical properties. The highesthardness that can be achieved about HB538, the tensile strength is 600 ~ 1100MPa, so the medium carbon steel is the most widely used for the productswith the medium strength requirement , Besides as the building material, itwidely used in manufacturing various mechanical parts.

High carbon steel (C: >0.6%)

Often being called tool steel, carbon content from more than 0.60% to 1.70%, can be quenched and tempered. Hammers, crowbars, etc. are made of 0.75% carbon steel; Cutting tools such as drill, wire tap and reamer are manufacturedof steel with carbon content from 0.90% to 1.00%.The higher the carbon content is, the greater the hardness and strength are, but the lower plasticity.

Carbon Steel Casting Process:

Same as alloy steel casting, carbon steel casting could be produced in two kinds of different casting processes: Water Glass Casting and Silica Sol Casting.

Water Glass Casting: This type of casting process can make carbon steel castings with tolerance CT7-CT8. Most of carbon steel castings use water glass casting process for its low cost. In China, around 70% casting foundries are water glass casting manufacturers.

Silica Sol Casting: Another lost wax casting method for carbon steel casting. This casting process can control carbon steel castings within tolerance CT5-6. Also the surface finish will be much better. The only consideration of selecting this process is its high production cost. If you have high demands on your carbon steel castings, we recommend this process.

Benefits of Carbon Steel Castings

Carbon steel is an extremely popular material option for steel castings, as it has a vast range of applications in several different industries. For the low material cost and a variety of material grades, carbon steel casting is commonly used and can improve its strength, ductility and other performance by heat treatment for industrial applications. Due to its ferromagnetic properties, this material is particularly useful for motor and electrical appliances. Carbon steel is safe and durable and has a high level of structural integrity, features that add to its popularity and make it one of the most created alloys in the world.

Carbon Steel Casting Manufacturer

As the leading investment casting supplier, TCC Casting can make carbon steel castings in all carbon steel alloys. Common used material grades of carbon steel castings in our company are AISI 1010, AISI 1020, AISI 1035, AISI 1045, AISI 1060, ect. Besides, we can also customize such carbon steel casting according to your material compositions. Our investment casting capabilities enable us to achieve tight tolerances in different dimensions for your cost savings.

We also have other capabilities of secondary operations such as machining, non-destructive testing, heat treat, and assembly. Like alloy steel castings & stainless steel castings, We can prove to supply carbon steel castings as good as any foundry can offer, better than most.

Please contact us if you have any inquiry of carbon steel investment casting, our material specialist will be here to support you .