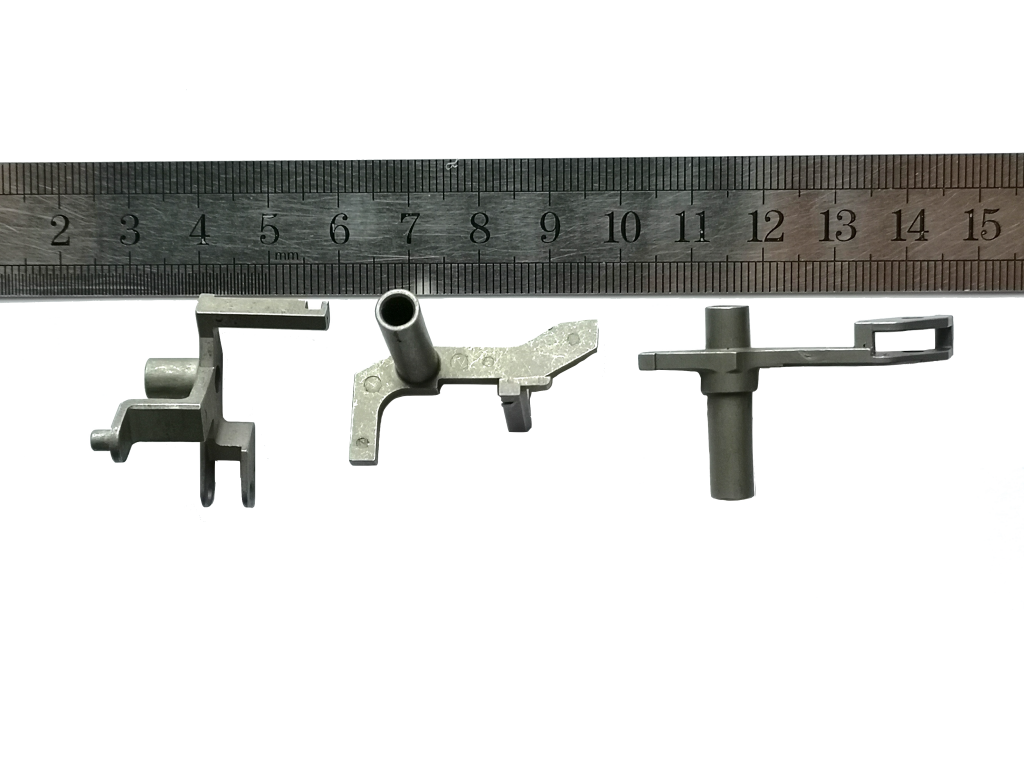

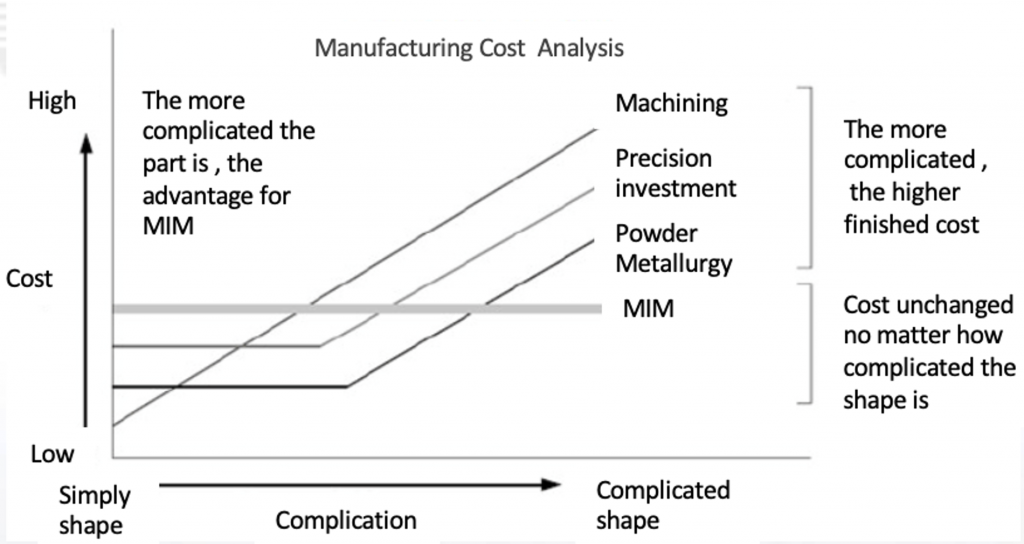

Metal injection molding (MIM) is an effective way to produce complex and precision-shaped parts from a variety of materials. This process produces parts for 50% less than the cost of CNC machining or casting. MIM is able to produce parts with complex shapes, superior strength and excellent surface finish with high volume manufacturing.

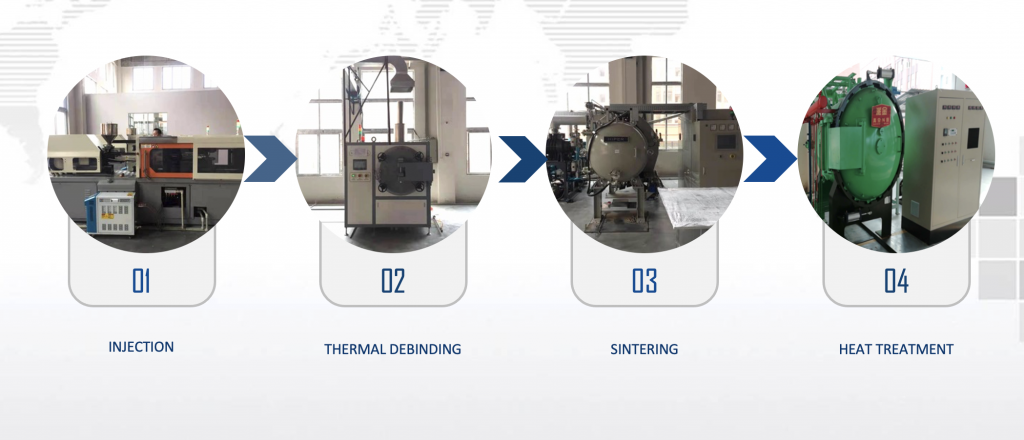

Metal Injection Molding(MIM)–Forming Process

MIM’s technology not only has less conventional powder metallurgy technology process, no or less cutting cutting cutting, high economic benefit, but also overcomes the traditional technology of powder metallurgy products low density low, uneven texture, mechanical performance, not easy forming thin-walled, after the shortcoming of complex structure, especially suitable for mass production of small metal parts, complex and has special requirements.

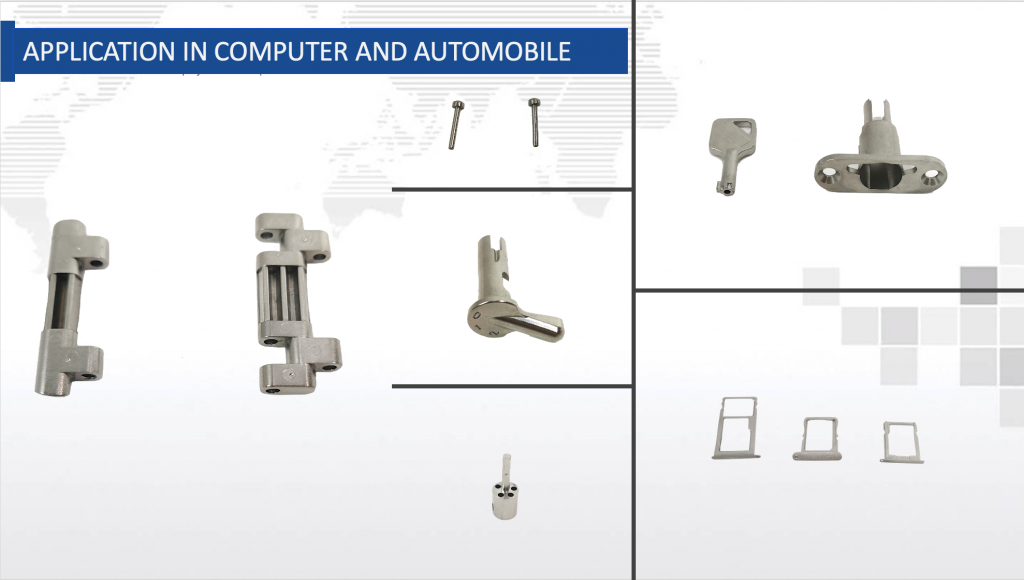

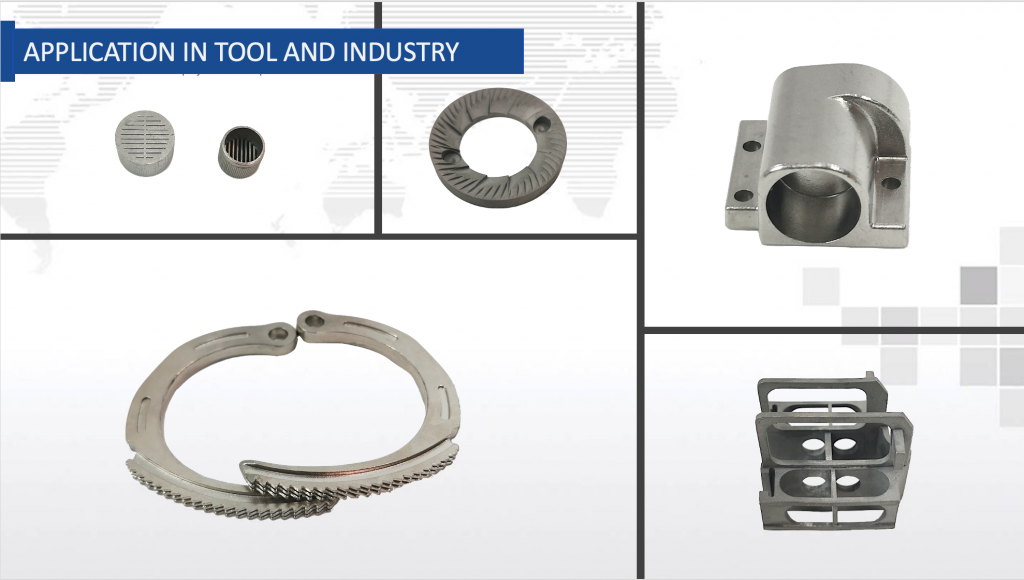

Metal Injection Molding(MIM)-Application Area

MIM process are found in numerous industries, including aerospace, automotive, consumer products, medical/dental, and telecommunications. MIM components can be found in cell phones, sporting goods, power tools, surgical instruments, and various electronic and optical devices.

How’s the Cost Compare to casting

By using this technology, skills and experience , TCC deliver a complete manufacturing solution for each project and application.For more information on metal injection molding and to determine if MIM is the best process for your part run, please feel free to contact us .