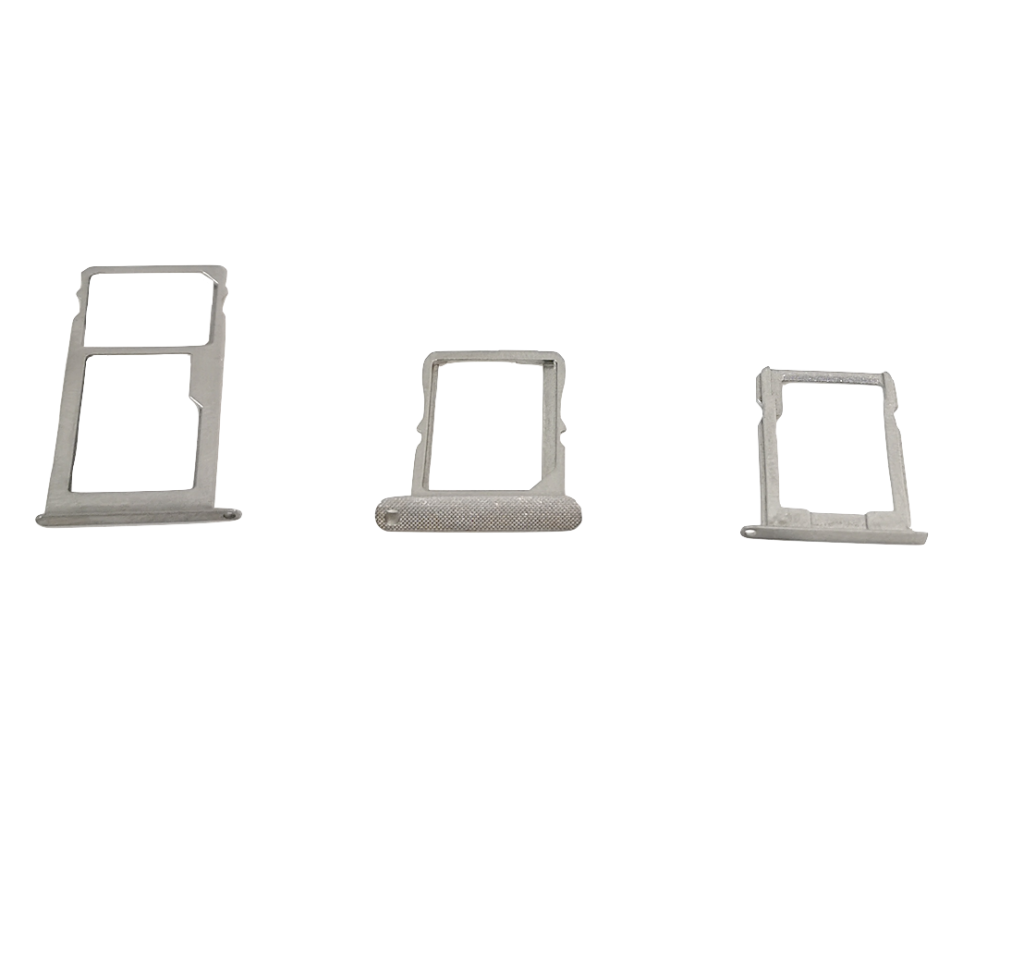

Metal injection molding for small connector

Metal injection molding is a metalworking process in which finely-powdered metal is mixed with binder material to produce a “feedstock” which is then shaped by injection molding.

The complex parts just need to be shaped in one step during the whole process. After molding, the part undergoes conditioning operations to remove the binder and densify the powder.

As the good performance on roughness , tolerance ,high efficiency than other technic .The metal injection molding market has grown quickly , especially some fields, eg,consumer electronics and IT sectors, medical and orthodontic fields and automotive industry.

The demand for small, sophisticated, high-volume components has made MIM thriving in the electronics area.

Connectors with complex geometries are now the main MIM products, and the miniaturization of electronic devices requires smaller components to achieve better performance at lower cost. This is where metal injection molding can take advantage of it.

Metal injection molding is used to produce lightning connectors for smartphone devices, which are tens of millions produced per week at peak production. This small, complex component with high-volume can be produced in multi-cavity molds to net-shape. Few other technologies can be compared with high volume capacity and tight tolerances of metal injection molding.

If you have some small parts need to design , from the material to the structure , our technician can design the good cost performance product for you .please contact us by email alina@tcc-casting.com